In the era of YouTube tutorials and “one-click” e-commerce kits, it’s easy to convince yourself that you can do anything. Last month, after looking at my fishbowl-clear SUV and then looking at the quotes for a professional window tint, I decided to take matters into my own hands. I ordered a pre-cut kit, grabbed a spray bottle, and prepared to save myself a few hundred Dirhams.

Was it a win? In the first ten minutes, I thought so. By the end of the weekend, however, I realized that I had made a massive technical error. Here is the breakdown of what actually happens when you try to DIY a car window tint in a home garage.

The Allure of the “Pre-Cut” Kit

The kit arrived with pieces of film supposedly cut to the exact dimensions of my windows. On paper, this removes the most dangerous part of the job: taking a razor blade to your glass. I cleaned the windows, sprayed the “slip solution,” and slid the film into place.

It looked easy. But as I started to squeegee the water out, the “nitty-gritty” reality of physics set in.

The Invisible Enemy: Static and Dust

The biggest hurdle for any DIYer in Dubai isn’t the film—it’s the air. A professional studio is a controlled, filtered environment. My garage, however, is a playground for static electricity and microscopic desert dust.

The moment you peel the backing off a window tint, the film becomes a giant magnet for every floating fiber in the room. I ended up with what pros call “contamination”—tiny white specks trapped forever between the film and the glass. In the shade, they are invisible. Under the harsh midday sun, they look like a constellation of mistakes.

The Mystery of the “Heat Shrink”

This was my biggest “regret” moment. I didn’t realize that car windows aren’t flat; they are curved in two directions. To get the film to lay flat on a rear windshield, you have to “heat shrink” it on the outside of the glass first to match the curvature.

Without a high-output heat gun and the muscle memory to know when the film is about to melt, I ended up with “fingers”—long, vertical air pockets that refused to stay down. I spent three hours chasing bubbles, only to have them reappear the next morning.

The Technical Gap: DIY vs. Specialist Film

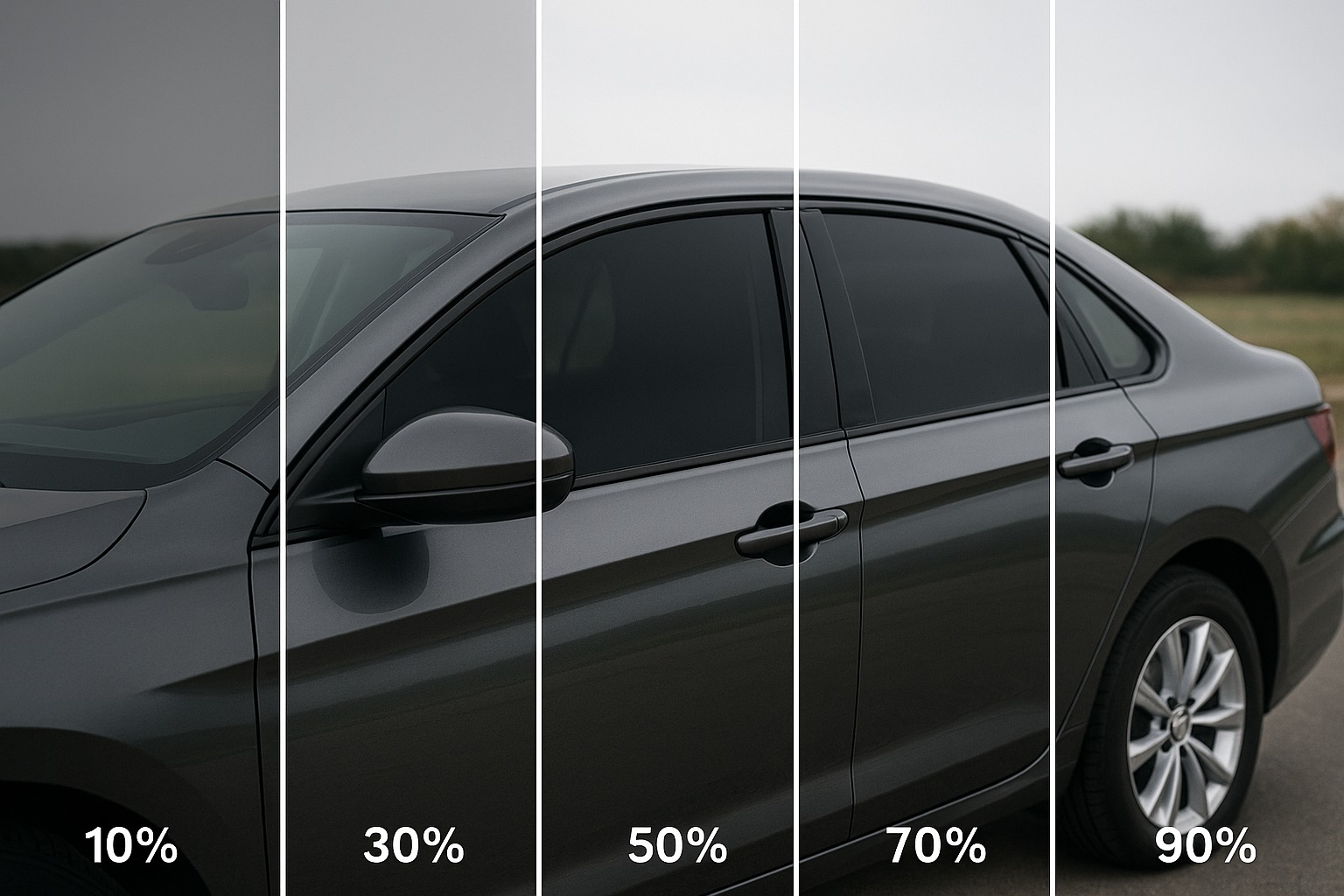

Beyond the installation, there is the issue of the material itself. Most DIY kits use “dyed” technology. It blocks light, but it’s essentially just a dark sticker.

When I eventually gave up and sought help, I realized the film I had bought had a Total Solar Energy Rejection (TSER) of about 15%. I was basically paying for shade, not heat rejection.

That’s why choosing the right detailer is the only way to get real performance. I ended up at RMA PPF, and the difference in their approach was eye-opening. They don’t just “install film”; they understand the chemical evolution of adhesives and the spectrally selective nature of nano-ceramic technology.

The team at RMA are genuine car enthusiasts who obsess over the nitty-gritty of the process—things I never even considered, like decontaminating the felt seals in the door or using a VLT meter to ensure RTA compliance. They treated my SUV with a level of excellence that a DIY kit simply cannot replicate.

The Verdict: Win or Regret?

If you’re looking for a “win” on a budget project car that stays in the garage, DIY might be fun. But if you care about optical clarity, 99% UV protection, and a finish that doesn’t peel the first time you hit 120 km/h on the E11, it’s a total regret.

The money I “saved” was immediately lost in the time I wasted and the cost of having the professional team remove my bubbly mess. In the world of car window tint, you aren’t just paying for the plastic—you’re paying for the environment, the tools, and the hands of a specialist who knows exactly how to handle high-end glass.