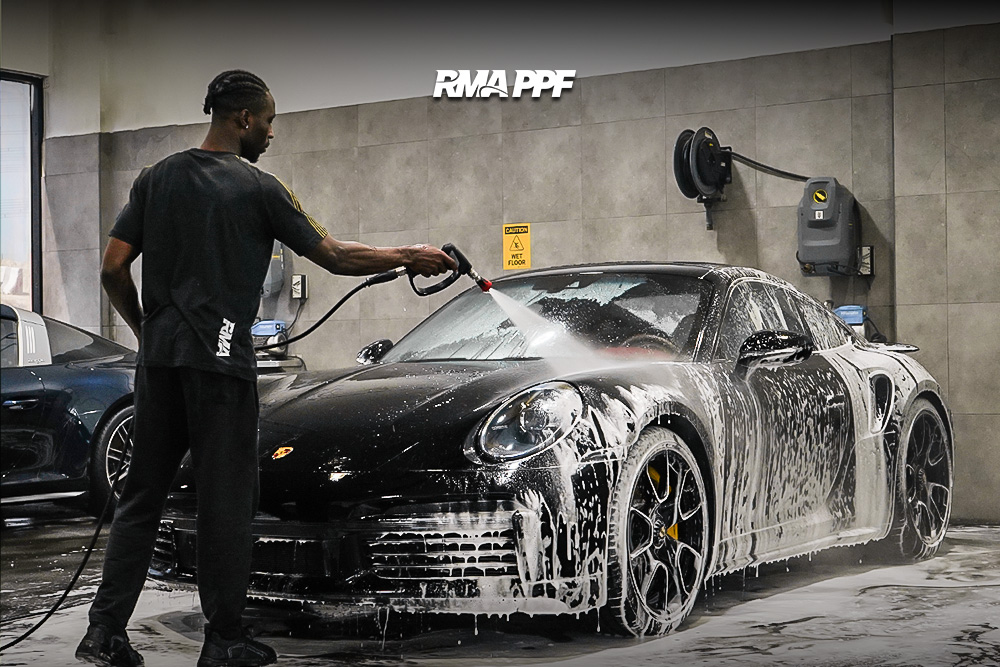

In professional car detailing, the foam cannon has become an icon. That thick, snowy layer of foam clinging to a vehicle isn’t just for aesthetics; it’s a critical tool in the pursuit of the safest wash possible. A quality foam application allows for contactless cleaning, dramatically reducing the risk of swirl marks and scratches.

But to truly master this technique, you must look beyond basic soap suds. The effectiveness of a foam pre-wash lies in two scientific principles: foam density and dwell time. Here is how professionals use these factors to lift grime safely before a wash mitt ever touches the paint.

1. Foam Density: The Power of Thickness

Foam density refers to how thick, rich, and stable the foam mixture is. It is controlled by the type of soap used (a dedicated snow foam concentrate) and the air-to-water ratio delivered by the foam cannon.

- Low Density (Thin Foam): Thin, watery foam runs off the vehicle quickly. It provides high lubrication but lacks the necessary structure to cling to the dirt. Its contact time is too short to effectively break down heavy grime.

- High Density (Thick Foam): Thick, shaving-cream-like foam is the goal. Its powerful surface tension allows it to cling aggressively to vertical surfaces. This structure encapsulates the dirt particles, suspending them within the foam layer and lifting them away from the car paint protection. This minimizes the chance of dragging abrasive particles across the paint when you start the contact wash.

A professional detailer calibrates their foam cannon meticulously to achieve a dense, stable foam that stays put.

2. Dwell Time: The Secret to Molecular Breakdown

Dwell time is the amount of time the foam is left on the vehicle before being rinsed off. This is where the magic of contactless cleaning truly happens.

- The Principle: Snow foam contains surfactants and cleaning agents that chemically loosen the bond between the road grime (traffic film) and the vehicle’s surface. Given time, the foam slowly dissolves oily residue, bug splatter, and environmental films.

- The Goal: The foam should be allowed to sit for 3 to 5 minutes without drying. This extended contact time gives the surfactants adequate opportunity to penetrate the grime. As the foam starts to break down and slide off the vehicle, it carries the loosened dirt with it.

If the foam dries before being rinsed, the cleaning agents stop working, and the residue can actually bake onto the paint, creating new water spot problems.

The Contactless Advantage in Car Detailing

Mastering foam density and dwell time drastically reduces the reliance on heavy scrubbing during the contact wash phase.

- Reduced Friction: By chemically loosening and removing up to 80% of the surface dirt in a contactless pre-wash, the friction introduced by the wash mitt is minimized, which is the key defense against swirl marks.

- Safety for Coatings: This technique is especially vital for vehicles protected by a ceramic coating or PPF coating. It ensures the protective layer is cleaned gently, preserving its slick, hydrophobic properties and extending its overall lifespan.

Achieving a truly flawless finish in car detailing always starts with a safe pre-wash. By treating foam density and dwell time as scientific necessities, professionals guarantee the vehicle is pristine before any wash mitt even touches the surface.