When you choose to protect your vehicle with a premium PPF automotive product like Profilm, the quality of the installation is just as important as the film itself. In Dubai’s demanding environment, a flawless installation is the only way to ensure your car protection film performs as intended for years to come. This isn’t a task for an amateur; it’s a precise craft that requires specialized training and a meticulous process.

This guide will walk you through what to expect from a professional Profilm installation and explain why choosing a certified installer is the most crucial step in the entire process.

The Professional Installation Process: A Meticulous Craft

A certified Profilm installer doesn’t just “slap on” the film. They follow a rigorous, multi-stage process that guarantees a seamless, bubble-free, and long-lasting finish.

1. Decontamination and Surface Preparation

This is the most critical stage, and it often takes longer than the installation itself. The car’s surface must be surgically clean. Our technicians perform a multi-step decontamination, which includes:

Deep Wash: A thorough cleaning to remove all surface dirt and grime.

Clay Bar Treatment: Using a clay bar to lift embedded contaminants like road tar, iron particles, and industrial fallout that a normal wash can’t remove.

Paint Correction (if needed): Any existing swirl marks, light scratches, or imperfections are polished out. This ensures that the PPF doesn’t magnify a flawed finish.

2. Precision Cutting

Unlike old-school methods that involved hand-cutting film on the car’s paint, a certified Profilm installer uses a digital cutting system. Profilm’s ProCut software has a vast library of templates for virtually every make and model. This ensures a perfect, computer-generated cut that fits every curve and edge of your vehicle with millimeter-level accuracy. This process is safer and delivers a superior result with no exposed edges.

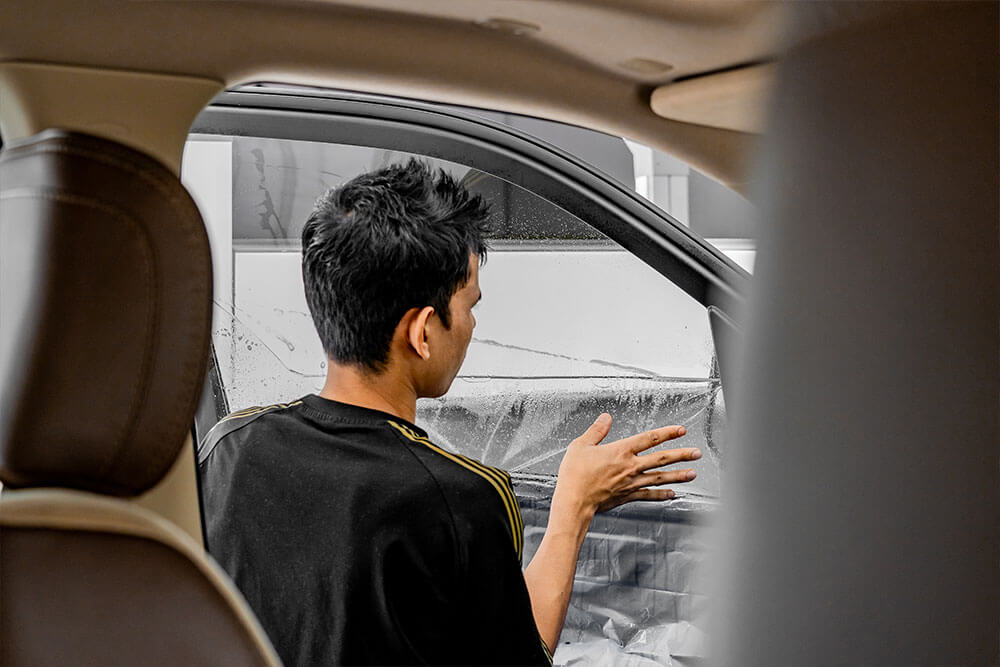

3. The Art of Application

With the surface prepped and the film precisely cut, the technician applies a slip solution to the car’s surface, which allows them to float the film into perfect position. Using specialized squeegees, they carefully work the film, pushing out every last bubble and crease. This step is a delicate dance of skill, pressure, and heat to ensure the film bonds perfectly to the paint without a single imperfection.

4. Post-Installation Inspection

Once the film is applied, our team performs a final, detailed inspection. We check every edge, seam, and curve to ensure a flawless finish. The car is then left to cure in a climate-controlled environment, allowing the adhesive to fully bond and any residual moisture to evaporate.

The Power of Certification: Why It Matters

When it comes to a premium paint protection film like Profilm, certification is your guarantee of quality. Here’s what that certification means for you:

Expertise You Can Trust: Certified installers have undergone extensive, hands-on training directly from Profilm. They are experts in their craft and understand the nuances of the product better than anyone.

Proper Tools and Techniques: Certification ensures that the installer has access to and knows how to use the correct tools, from the digital cutting software to the heat guns and squeegees.

Warranty Integrity: A manufacturer’s warranty is often only valid if the installation is performed by a certified professional. By choosing a certified installer, you are protecting your investment and ensuring that your warranty will be honored.

At RMA PPF, our team is certified in Profilm installation, which means every PPF car that leaves our facility has received the highest standard of care. We combine Profilm’s cutting-edge technology with our own meticulous craftsmanship to deliver an unparalleled result.